When the Winds Rise: Commercial Roofs Built for New Orleans Storms

The Problem: Storms Keep Testing Gulf South Roofs

In New Orleans, storms aren’t rare events — they’re a recurring test of how well your building is built. Over the last two decades, hurricanes and tropical storms have shown the cost of weak roofing systems for commercial and industrial facilities:

Katrina (2005): Winds over 100 mph peeled the Superdome’s roof and stripped coverings from warehouses across Orleans Parish.

Zeta (2020): With gusts topping 90 mph, panels and coverings lifted at corners and seams — the exact points where uplift forces hit hardest.

Ida (2021): Gusts near 100 mph in New Orleans tore entire roof systems open, shutting down businesses for weeks as water ruined equipment and inventory.

Olga (2019): Even at tropical storm strength, Olga exposed leaks in aging commercial roofs, proving it doesn’t take a Category 4 to cause costly downtime.

The lesson is clear: uplift forces pull at seams, edges, and fasteners. Once the seal breaks, water intrusion brings operations to a halt.

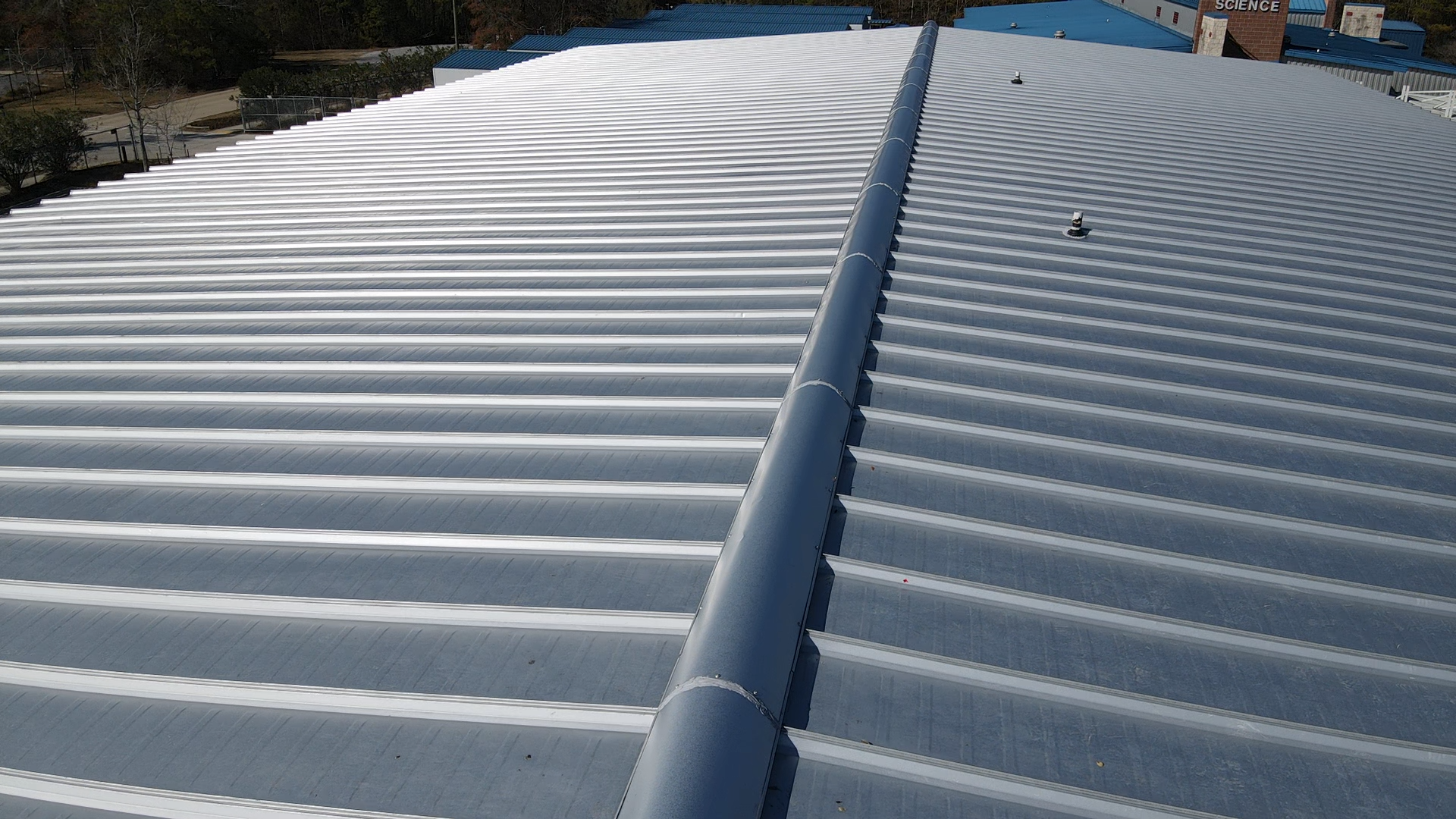

The Butler® Solution: MR-24® Standing Seam Resilience

Butler’s MR-24® roof system was engineered from the start to resist the very failure modes that storms exploit.

Watertight Seams: The 360° Pittsburgh double-lock seam is field-finished with nearly 3,800 pounds of pressure, creating a continuous barrier against hurricane-driven rain.

Designed for Movement: Floating clips let panels expand and contract with Louisiana’s extreme temperature swings without loosening fasteners or tearing at seams.

System Integration: Factory-punched components ensure precise alignment and performance, eliminating weak spots caused by patchwork systems or inconsistent installation.

Galvalume® Panels: Made with 55% aluminum-zinc coating, Galvalume® resists corrosion and delivers service lives of 40+ years. A 26-year-old roof in New Orleans still performs despite constant humidity and runoff exposure.

Certified and Proven in the Field

MR-24® doesn’t just promise durability — it’s proven through decades of testing and performance:

UL Class 90 uplift certification — the first of its kind.

ASTM E 1592 structural testing — the industry benchmark.

Factory Mutual 1-120 ratings — delivering hurricane-level resistance.

Developed with the U.S. Army Corps of Engineers, ensuring compliance with the toughest Gulf Coast project standards.

Certified for Hurricane Country

MR-24® is more than strong on paper — it’s been tested and certified to withstand hurricane-level conditions:

First commercial standing seam system to achieve UL Class 90 uplift certification.

Tested to ASTM E 1592, the benchmark for structural performance.

Factory Mutual approvals up to 1-120, covering the highest wind pressures commercial facilities face.

Developed in consultation with the U.S. Army Corps of Engineers, aligning with the standards used in Gulf Coast infrastructure projects.

The Payoff: Security and Value for New Orleans Businesses

For facility owners, a storm-tested roof means more than protection. It means:

Longevity: MR-24® roofs consistently perform for 40+ years, far exceeding conventional systems.

Reduced Maintenance: Annual upkeep runs five to ten times lower than single-ply or built-up roofing.

Life-Cycle Savings: Independent studies show six-figure advantages over 30 years compared to EPDM membranes.

Energy Efficiency: ENERGY STAR® cool-roof finishes cut cooling costs by up to 40% during New Orleans summers.

When the winds rise again — and they will — MR-24® gives commercial operators confidence their facilities will stay secure.

Contact Gulf South Metal Works today to schedule a consultation and put Butler’s storm-proven roofing to work for your business.